Categories

- Plastic Spray Nozzle

- Adjustable Ball Type Small Hole Rotating Flat Fan Full Cone Nozzle

- Spiral Tank Wash Nozzle

- Tank Cleaning Full Cone Nozzle

- Water Tank Cleaning Eductor Nozzle

- Garden liquid insecticide nozzle

- Anti-clogging Water Tank Nozzle

- Water Tank Cleaning Nozzle

- Stirring Eductor Nozzle

- Stirring Jet Nozzle

- Mixing Eductor Nozzle

- Anti-clogging Jet Nozzle

- Rotary Ball Tank Cleaning Nozzle

- Industrial Nylon Adjustable Ball Nozzle Assembly

- ABS Plastic Adjustable Ball Clamp Nozzle

- Industrial Stainless Steel Adjustable Ball Nozzle

- Adjustable ball nozzle for washing

- Agricultural Stainless Steel Adjustable Ball Nozzle

- Adjustable Ball Joint Mounts

- Adjustable Ball Nozzle

- Water jet cleaning full cone nozzle

- Square Spray Defoaming Quick Install Spray Nozzle

- Hand-held disinfectant nozzle

- Flange 4-10 Full Cone Spray Nozzle, Full Jet Nozzle

- Angle Type Removable Cap And Vane Full Jet Spray Nozzle, Water Vortex Nozzle

- Nozzles for garden fertilization

- Stainless steel clean full cone nozzle

- Agricultural insecticidal fertilizing nozzle

- Full Cone Brass Fuel Oil Burner Spray Nozzle

- Cooling And Washing Tower Max Passage Full Cone Spray Nozzle

- Heat-Resistant Plastic Full Cone Spray Nozzle

- Full cone nozzle for factory washing

- Industrial full cone jet nozzle

- Solid Cone Spray Full Cone Nozzle

- Bb 1/4 Stainless Steel Water Washing Full Cone Jet Spray Nozzle

- 1/2 Hh Type PP Full Cone Water Spray Nozzle

- Bb Full Cone Plastic Nozzle, Plastic Spray Nozzle

- Full cone nozzle for irrigation

- Factory Wide-Angle Water Spray Jetting Brass Full Cone Nozzle

- Full cone nozzle for dust removal

- Removable Cap And Vane Full Cone Spray Nozzle

- Full Cone, Water Spray Nozzle

- Factory Made Full Cone Spray Gun Nozzle

- Plastic adjustable ball cone nozzle

- Stainless Steel Full Cone Spray Water Nozzles

- Agricultural drone spray nozzle

- Plastic perfume cosmetic jar nozzle

- Full Cone Spiral Nozzles /Desulphurization Spray Nozzles

- Weed Control Hose End Weedkiller Spray Nozzle

- Silicon Sintering Carbide Spiral Full Cone Spray Nozzle

- Cooling tower full cone spiral nozzle

- Brass jet full cone nozzle

- Industrial Metal Full Cone Water Spray Nozzle

- Plastic Mist/Water/ Spray Nozzle With Full Cone

- Silicon Carbide SiSiC Spiral Full Cone Spray Nozzle On Large Boiler

- Stainless steel full cone atomizing nozzle

- Double Gun Garden Hose Water Full Cone Spray Nozzle

- Stainless Steel Bb Full Jet Solid Cone Spray Nozzle

- Industrial full cone flame spray nozzle

- Factory custom atomizing nozzle

- Full Cone Square Spray Nozzle

- Stainless steel fountain nozzle

- Full Cone Ink Washing Spray Nozzle

- Narrow angle full cone water nozzle

- Quick disassembly and assembly of full cone nozzle

- Plastic Quick Connected Hollow Cone Cleaning Nozzle

- Plastic Quick Detachable Full Cone Water Spray Nozzle

- Quick Install PP Full Cone Shape Water Spray Nozzle

- Detachable full cone nozzle for dust removal

- Flat Fan Liquid Spray Pipe Mounting Clamp Nozzle

- Stainless steel wide-angle flat fan nozzle

- Stainless steel high pressure flat fan nozzle

- Industrial Spray Nozzle PP Flat Fan Nozzle

- Industrial flat fan spray nozzle

- Flat Fan Spray Spray Nozzle

- Ultra Strong Impact Flat Fan Cleaning Water Spray Nozzle

- Belt Pulley

- alternator freewheel clutch pulley

- Cast iron ship pulley

- Factory custom cast iron pullYe

- alternator freewheel clutch pulley

- Factory made cast iron pulleys

- OEM Service, Cast Iron Pulley

- Double groove pulley for electric motor

- Steel double groove pulley

- Cast iron pulley

- Double set screw cast iron pulley

- Forged cast iron double groove pulley

- Custom processing cast iron pulley

- Custom finishing pulley

- Pulleys for automated machinery

- Standard cast iron V belt wheel

- High quality cast iron V belt wheel

- Factory made pulleys

- Steel pulley

- Customized high-quality V-belt wheels

- Metal pulley

- Agricultural machinery V belt wheel

- Customized Double Groove V Belt Wheels for Industrial Use

- Customized double groove V belt wheel

- Cast iron double groove pulley

- Cast iron double groove pulley for motor

- Cast iron double groove V belt wheel

- CNC custom double groove cast iron pulley

- Customized Die Casting Automobile V Belt Wheel

- Factory customized standard V belt wheel

- V-belt pulley for automobile

- V-belt pulleys for large machinery

- OEM Service,V Belt Pulley

- V-belt pulleys for agricultural machinery

- Industrial V-belt pulley

- Factory wholesale V-belt pulley

- Factory customized die-cast pulley

- CNC machining, OEM service,V-Belt Pulley

- Standard V-belt pulley

- Custom die-cast pulley

- Motor V belt wheel

- Factory customized V-belt pulley

- Custom die-cast pulley

- Plastic V Belt Pulley

- Alloy V Belt Pulley

- Metal V Belt Pulley

- Gear

- Galvanized Hypoid Gear

- Reducer Hypoid Gear

- Gearbox Hypoid Gear

- High Speed Hypoid Gear

- Motor Cross Helical Gear

- Sewing Machine Bevel Gear

- Motor Cross Helical Gear

- Reducer Cross Helical Gear

- Industrial Cross Helical Gears

- Gearbox Cross Helical Gear

- Carbon Steel Cross Helical Gears

- Crossed Helical Gears Screw Gears

- Brass Cross Helical Gears

- Angle Grinder Bevel Gear

- Automotive Bevel Gears

- Brass Bevel Gear

- Differential Spiral Bevel Gear

- Pinion Worm Gear

- Spiral Bevel Gear

- Carbon Steel Bevel Gears

- Gearbox Inline Helical Gear

- Inner Planetary Gear

- Spur Internal Gear

- Internal Helical Gear

- Plastic Double Pinion Internal Gear

- Planetary Ring Internal Gear

- Industrial Bevel Gears

- Rolling Mill Double Helical Gear

- Double Helical Gears For Agricultural Machinery

- Heavy Machinery Double Helical Gear

- Carbon Steel Double Helical Gear

- Customized Double Helical Gear

- Industrial Alloy Steel Double Helical Gears

- Stainless Steel Double Helical Gear And Gear Box

- Industrial Double Helical Gears

- Steel Double Helical Gear

- Internal Gears For Tractors And Cranes

- Industrial Internal Gear

- Steel Internal Gear

- Internal Spur Gear

- Involute Internal Gear

- Automotive Hypoid Gear

- Stainless Hypoid Gear

- Face Gear For Calibrication Meter

- Aircraft Face Gear

- Automotive Face Gear

- Metal Screw Gear

- Plastic Screw Gear

- Automotive Bevel Gear

- Plastic Bevel Gear

- Metal Bevel Gear

- Aircraft Bevel Gear

- Medical Bevel Gear

- Precision Bevel Gear

- Medical Double Helical Gear

- Aircraft Double Helical Gear

- Automotive Double Helical Gear

- Metal Internal Gear

- Automotive Internal Gear

- Plastic Internal Gear

- Aircraft Internal Gear

- Aircraft Helical Gear

- Automotive Helical Gear

- Metal Helical Wheel

- Metal Helical Gear

- Precision Helical Wheel

- Steel Helical Gear

- Precision Helical Gear

- Brass Helical Gear

- Automotive Plastic Helical Gear

- Aircraft Plastic Helical Gear

- Medical Plastic Helical Gear

- Plastica Helical Wheel

- Stainless Helical Gear

- Automotive Steel Spur Gear

- Aircraft Brass Spur Gear

- Automotive Brass Spur Gear

- Medical Stainless Spur Gear

- Aircraft Stainless Spur Gear

- Automotive Stainless Spur Gear

- Medical Plastic Spur Gear

- Automotive Metal Spur Gear

- Aircraft Metal Spur Gear

- Aircraft Spur Gear

- High Precision Aircraft Spur Gear

- Automotive Spur Gear

- Higher Precision Spur Gear

- Aircraft Steel Spur Gear

- Automotive Plastic Spur Gear

- Aircraft Plastic Spur Gear

- Medical Brass Spur Gear

- Gear Shaft

- CNC Motor Gear Shaft

- Custom steel straight shaft

- 60 Case Quick Shaft – Straight, Chrome Plated, Inch

- 60 Case LinearRace – Straight, Inch

- Planet Propeller Transmission Spline Gear Shaft

- Straight shaft with thread at both ends

- Factory custom stepped linear axis

- Custom linear axis

- Straight shaft with retaining ring groove at both ends

- Machined linear axis

- Factory customized one end with guiding linear axis

- Custom One End Tapped Precision Hollow Linear Shaft

- Custom Both Ends Threaded Precision Linear Shaft With Undercut

- Linear Shaft – One End Tapped Pilot, One End Tapped Or Threaded Precision

- One End Tapped Precision Hollow Linear Shaft

- One End Threaded Precision Linear Shaft With Undercut

- Straight-type Stainless Steel Series Linear Shaft

- Precision Linear Shaft With Key Groove On One End

- Both Ends Threaded Precision Linear Shaft With Undercut With Wrench Flats Or Cross Drilled Hole

- One End Threaded, One End Tapped Precision Linear Shaft – Inch Measurements

- Threaded linear shaft

- One End Stepped And Tapped Or Not-Tapped, One End Threaded Precision Linear Shaft

- CNC machining tapping linear axis

- Factory customized linear axis

- 60 Case LinearRace – Straight Ball Groove, Inch

- One End Stepped, Tapped Or Not-Tapped Precision Linear Shaft

- CNC machining, OEM service, linear axis

- 60 Case LinearRace – Straight, Inch

- One Tapped End Precision Linear Shaft – Inch Measurements

- Worm Gear

- High Precision Metal Worm Wheel

- Precision Plastic Worm Drive

- Aircraft Worm Gears

- Plastic Worm Wheel

- Cylindrical Worm Wheel

- POM Worm Wheel

- High Precision Metal Worm Wheel

- High Precision Alloy Worm Wheel

- Auto Precision Worm Gears

- Cylindrical Worm Wheel

- Precision Plastic Worm Drive

- Precision Alloy Worm Drive

- Coupling

- Die Casting

- Stainless Steel Triangle Bracket

- Stainless Steel Adjuster

- Custom Anchors For Aluminum Extrusions

- Custom Leveling Feet

- 5 Series R-Shaped 20×40 Aluminum Extrusion

- Gussets – Thread Hole Mounting

- Gussets – Thru Hole Mounting

- Gussets With Thru Hole – Hole Position Configurable

- Bridge Gussets

- Custom Gussets With Tapped Holes

- Economy Gussets – Precision Casting, Through Hole

- Lightened Gussets With Tapped Hole

- Standard Perpendicularity Gussets With Thru Hole

- Gussets With Tapped Holes

- Cast Iron Diagonal Pin Precision Angle Plate

- Precision Angle Plates With Configuralbe Hole Locations

- Custom Drilling Corner Plate

- Mounting Surface Tapped Angle Plates

- Wide Angle Plates

- Mounting Hole Selectable Hole Position Fixed Angle Plates

- Precision Angle Plates With Pre-Drilled Holes

- Welded Small Angle Plates

- Welded Angle Plates With Configurable Hole Position

- Standard Dimensions No Holes Cast Iron Angle Plates

- Precision Angle Plates Without Holes

- Customized Precision Drilling Angle Plate

- Standard Dimensions Aluminum Angle Plates

- 5 Series L-Shaped 20×40 Aluminum Extrusion

- 5 Series R-Shaped 20×40 Aluminum Extrusion

- 8 Series Triangle 45 Degree Aluminum Extrusion

- 90 Degree Curved 40×40 Aluminum Extrusion

- 8 Series 40×40 Aluminum Extrusion – One Closed Side

- 5 Series 20×20 Aluminum Extrusion – Quarter Round

- HFS6 Series Aluminum Extrusions

- 20×20 Aluminum Extrusion Two Adjacent Closed Sides

- 8-45 Series 100×200 Aluminum Extrusion

- 8-45 Series 100×100 Aluminum Extrusion

- 5 Series 40×60, 40×80 Aluminum Extrusion

- 8 Series 40×160 Aluminum Extrusion

- 8 Series 40×120 Aluminum Extrusion

- 8-45 Series45x90 Aluminum Extrusion

- Aluminum Extrusion W/ Milled Surfaces

- 8 Series 80×160 Aluminum Extrusion

- 5 Series 25×25 Aluminum Extrusion

- 6 Series 60×60 Aluminum Extrusion

- 8-45 Series 45×45 Aluminum Extrusion

- 8 Series 80×80 Aluminum Extrusion

- 3 Series 15×15 Aluminum Extrusion

- Economy Type Adjuster

- Carbon Steel Anchor Bracket

- Stainless Steel Adjuster

- Floor Stoppers For Aluminum Extrusions

- Custom Anchors For Aluminum Extrusions

- Heavy Anchors For Aluminum Extrusions

- Custom Leveling Feet

- Photovoltaic Bracket

- 3D Printed Parts

- 3D Printing Rapid Prototyping

- Drawing Customized Model 3D Printing

- 3D Printing Of Precision Auto Parts

- 3D Printer Fdm 3d Printer X Plus Smart Printing Large Size Printing Size 200*200*200mm

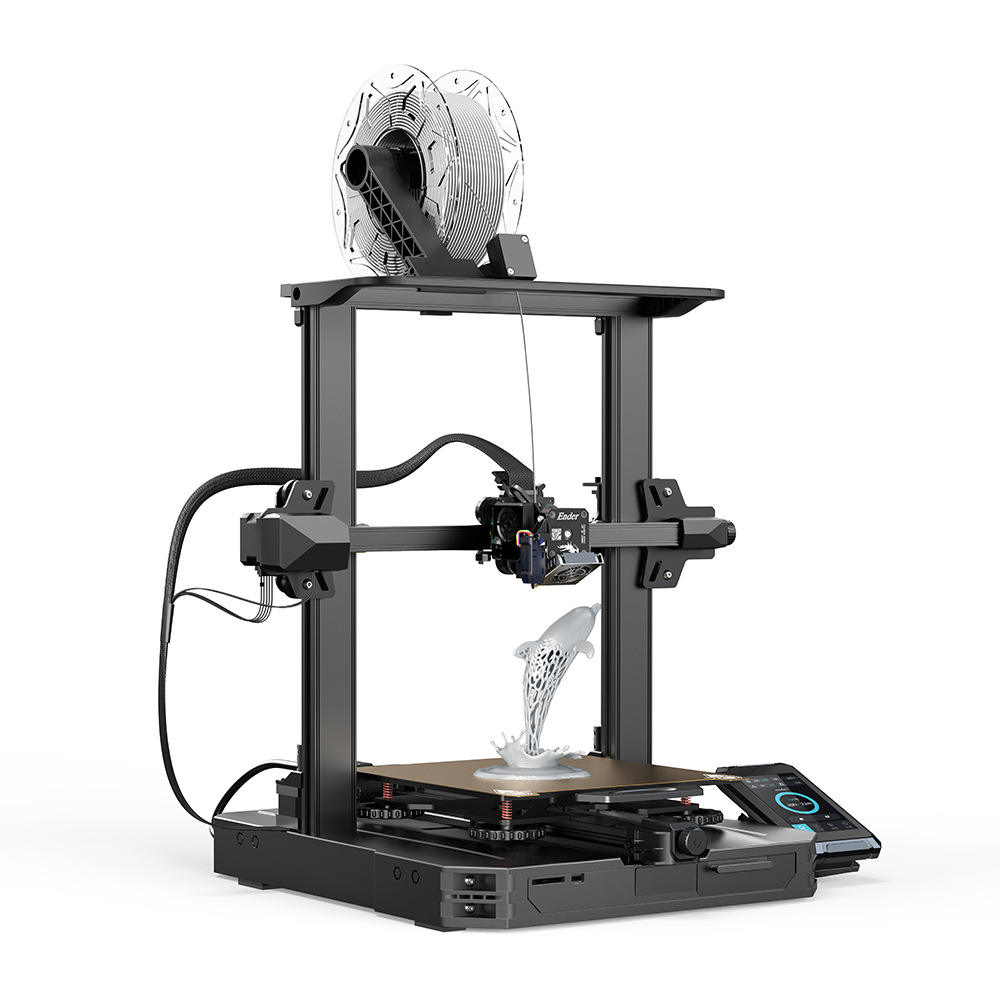

- Auto FM Silent 3d Printer Ender-3 S1 Pro Laser Engraving Printer/Metal Double Gear Proximal Extruder Printing Size 8.7*8.7*10.6

- Injection Products

- Custom Made

Contact Us

- Phone+86 18859257178

- Emailsarui@saruimic.com

- AddressRoom 1603-3, No. 63, Xishanwei Road, Phase III, Torch High tech Zone, Xiamen

Description

8-45 Series 100×100 Aluminum Extrusion

Specifications

| Part Number | – | L |

| GFS8-100100 | – | 800 |

| KGFS8-100100 | – | 4000 |

■Configurable Length Extrusions

| Type | [ M ]Material | [ S ]Surface Treatment | Part Number | L 0.5mm Increment | Mass kg/m |

Sectional Area mm2 | Cross Sectional Moment of Inertia mm4 | |

| ℓx | ℓy | |||||||

| GFS | 6061-T6 Aluminum Alloy Equivalent | Clear Anodize | GFS8-100100 | 50~4000 | 10.68 | 3957 | 465.8×104 | 465.8×104 |

[ ! ]Applicable to 6000mm depending on products.

■Fixed Length Extrusions (Effective Length 4000mm)

[ ! ]Part numbers beginning with the character “K” indicate Fixed Length Extrusion.

| Type | [ M ]Material | [ S ]Surface Treatment | Part Number | L mm |

Sectional Area mm2 | Cross Sectional Moment of Inertia mm4 | |

| ℓx | ℓy | ||||||

| GFS | 6061-T6 Aluminum Alloy Equivalent | Clear Anodize | KGFS8-100100 | 4000 | 3957 | 465.8×104 | 465.8×104 |

[ ! ]”Effective Length 4000mm” represents the extrusion with 4000mm or more effective length.

(several cm)

8-45 Series 100×100 Aluminum Extrusion

Alterations

Alterations are not applicable to all frames.

| Category | Alteration Names | Codes | Explanations |

| Aluminum Frame Alteration Summary/Chamfer/Part# Labeling Service | |||

| End Tapping | End Tapping on Center Hole | LTP/RTP/TPW LHP/RHP/HPW |

Add tappings on frame ends. |

| End Tapping 4 Corner Holes | LSP/RSP/SPW | ||

| Specify How to Cut | Precision Cut | SC | Change total length tolerance. (L±0.5→L±0.2)

Available only for L≦1500 |

| 45 deg Cut | L_T45/R_T45 | Cut at 45 deg angle. | |

| Wrench Access Holes | Wrench Access Hole at Fixed Position | LWP/RWP | Add wrench access holes at fixed position for blind joints. |

| Wrench Access Hole at Specified Position | AH/BH/AV/BV | Add wrench access holes at specified position for blind joints. | |

| Counterbores | Counterbores at Specified Position | Z6/XA100 | Add counterbores at specified position. Use the holes for connecting the frames and a table top. |

| Holes for Specific Blind Joint Type | D Hole | LDH/RDH | Add holes needed for Single Joint connection. |

| S Hole | LSH/RSH | Add holes needed for pre-assembly double joint connection. | |

| M Hole | LMH/RMH | Add holes needed for post-assembly double joint connection. | |

| L Hole | JLP/KLP | Add holes needed for parallel joint connection. | |

| Other Alterations | GNFS/GFS Series End Tapping | LTS/RTS/TSW | Add end tappings on high rigidity frames. |

| HFSR Series End Tapping | LTS/RTS/TSW | Add end tappings needed for adding a protection cover on the end fo HFSR series frame. |

8-45 Series 100×100 Aluminum Extrusion

Basic Information

| Standard Extrusion Size(mm) | 100 | Extrusion Size | 100×100 | Extrusion Shape | Square |

| Number of Extrusion Slots | 2 Slots-2 Slots | Extrusion Type | GFS (High Rigidity) | Surface Finish | Clear Anodize |

| Number of Grooved Surfaces | Four Side Slots | Surface Milled | None | Material | 6061 Aluminum AlloySS-T6 Equivalent |

| Extrusion Size – Width (A)(mm)(mm) | 100 | Extrusion Size – Thickness (T)(mm)(mm) | 100 | L Dimension Fixed, Specified | Configurable |

Experience

Xiamen Kangfuxiang Machinery provides parts design, prototyping, mold design, mold production, mass production and internal assembly services. We work with many customers all over the world and have a deep understanding of the mold industry. Our experience ranges from simple designs to challenging technical parts.